1) to enhance oil storage stability;

2) to improve the oil flavor;

3) to improve the color of oil;

4) for the deep processing of oil products to provide raw materials.

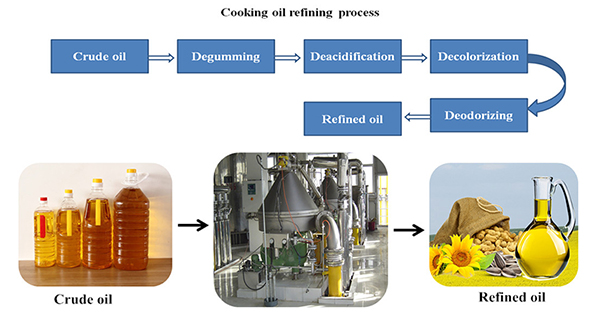

Soybean crude oil after degumming, deacidification, bleaching, deodorization and other process steps, while adding edible phospholipids, alkali, decolorizing activated clay and other technology accessories, after centrifugal separation, bleaching adsorption, filtration separation, high temperature distillation deodorization process to remove impurities And affect the color of oil, stability and flavor of the ingredients, improve oil quality, flavor and storage stability.

1) Degumming

The process of removing the peptizing impurities in the oil is called degumming.Our method of use in the actual production is a special wet degumming, is a kind of hydration degumming method.

The basic principle of oil hydration degumming is the use of phospholipids and other glue-soluble impurities in the hydrophilic, a certain amount of electrolyte solution added to the oil, so that colloidal impurities in water, condensed and oil separation. Which mainly in the colloidal phospholipids.In the case of little water, the phospholipids in the oil dissolve in the form of salt and disperse in the oil. When the water is increased, it absorbs water and increases the volume, and the colloidal particles attract each other to form larger micelles. The difference in proportionality can be separated from the oil.

2) Deacidification

Vegetable fats always have a certain amount of free fatty acids, depending on the quality of the oil.Seed immaturity, high seed breakage, etc., is the cause of high acid value of the reasons, especially in high water conditions, the preservation of oil is very negative, it will make the free acid content increased and reduced The quality of the grease, so that the deterioration of food quality.The main method of deacidification is alkali refining and distillation. Distillation method, also known as physical refining method, used in high acid value, low-quality oil refining.

3) Decolorization

Vegetable oil pigment composition is complex, mainly including chlorophyll, carotene, flavonoids, anthocyanins and certain sugars, protein decomposition products.Grease decolorization commonly used adsorption decolorization method.Decolorization adsorption principle is the use of strong adsorption characteristics of adsorbents capable of adsorbing the dye in the hot oil and other impurities, but also the adsorbed dye was removed by filtration and impurities removed in the adsorbent simultaneously, so as to achieve the purpose of purification decolorization.

4) Deodorization

All kinds of vegetable oil has its own unique flavor and taste, the deacidification, decolorization of the oil will also have a trace of aldehydes, ketones, hydrocarbons, low molecular weight fatty acids, glycerides and white clay, residual solvent Of the smell, etc., to remove these undesirable processes called deodorization.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.