Wheat milling is a complex process aimed at converting wheat grains into wheat flour suitable for different needs and separating out the by-products. This process mainly includes the following key steps and principles:

Through the above steps, wheat is processed into wheat flour suitable for different needs, while by-products such as wheat germ are separated. The entire milling process is a purely physical process that involves a cycle of multiple steps to ensure the quality and purity of the flour.

Corn flour milling is a process of processing corn into starch or corn flour, which mainly involves grinding, sieving, flour cleaning, and other steps. This process includes the following key stages:

Throughout the entire processing process, a variety of equipment and techniques are used to ensure that corn is effectively processed into high-quality starch or flour.

Rice Mill ProcessingHuatai provides customers with one-stop efficient rice milling processing technology and equipment.

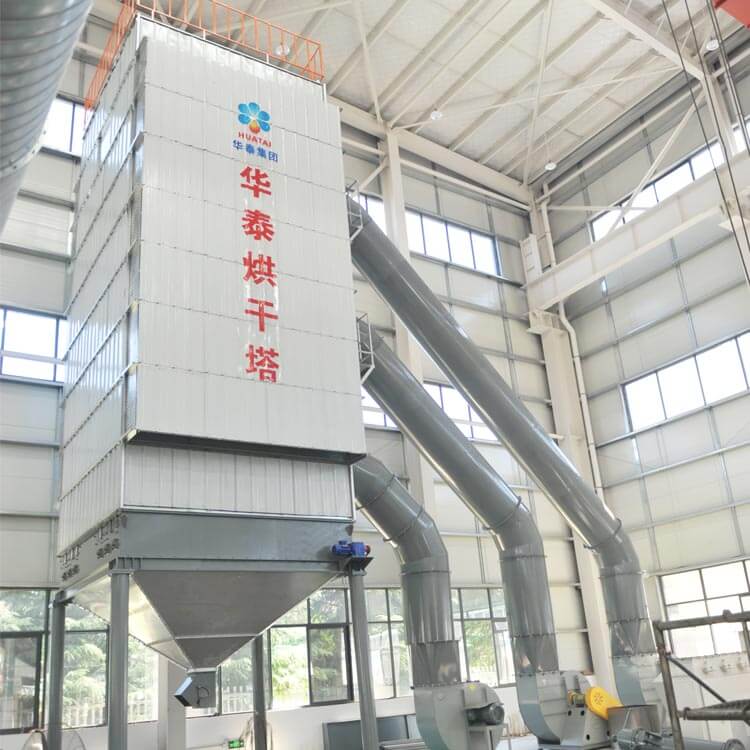

HuaTai grain drying tower is a commonly used grain drying equipment. It evaporates the moisture in the grain through the contact between hot air and grain, thereby achieving the drying effect. Its working principle mainly includes three parts: the generation, transmission and drying process of hot air.

The corn deep processing machinery adopts combined dehusking and degerming technology, and it can produce different granularity of low-fat corn grits, corn flour, and corn bran. They are also ideal foods for urban residents. Corn bran can be used for feeds.

The grains milling production line includes a grain cleaning machine, a net conveyor auger, a granary Run, an elevator, a double peeling machine , four set 30 novel milling machine and so on, one-stop production from raw materials to finished products, which can produce various specifications high mesh powder. It also can be processed buckwheat, millet, oats, beans, cowpea, beans, peas, beans, kidney beans, lentils, sorghum, black rice, and other grains.

Wheat flour mill processing equipment division stand-alone devices and equipment, can co-production special flour, flour, marking powder, 200 tons more than the specifications of flour can produce all kinds of food to meet the needs of the food industry.

The TQSF-Gravity grading stoner is mainly used for clean up, light mixed sand, soil, and high-density impurities.

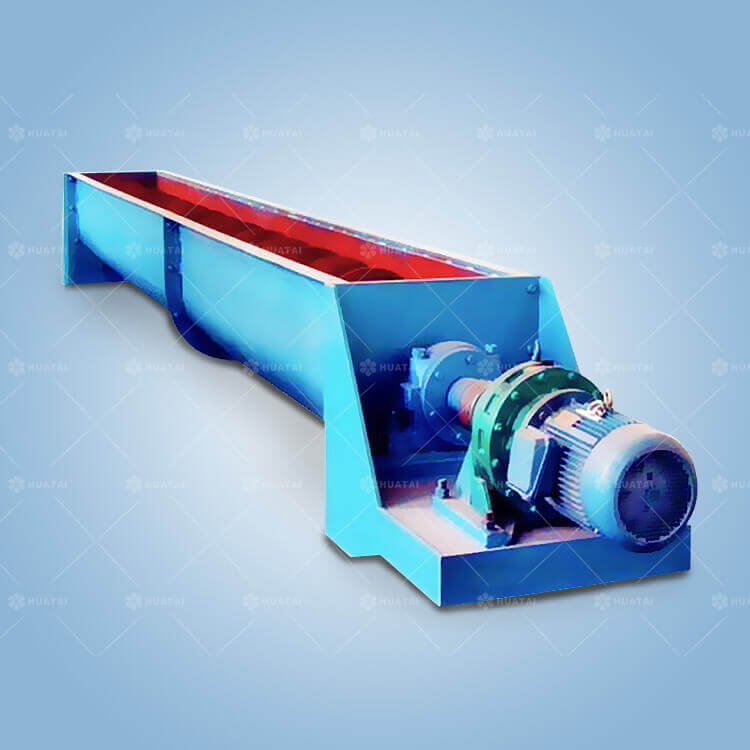

The TLSS-screw conveyer is used for the level of material conveying, with the aid of a rotating spiral blade thrust the raw material will be conveyed along the slot machine.

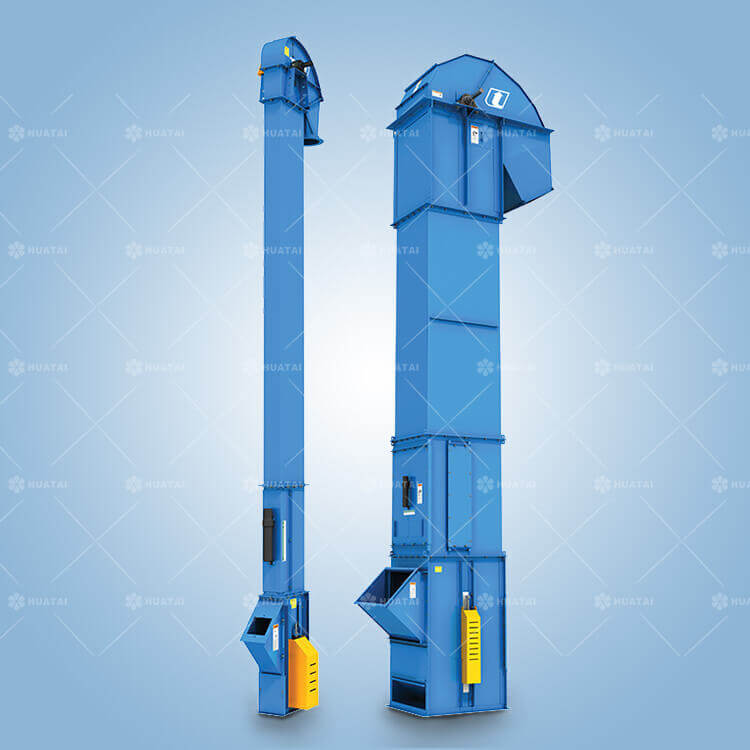

The TDTG bucket elevator is used for granular and powdered materials transportation, stable output, and low noise characteristics.

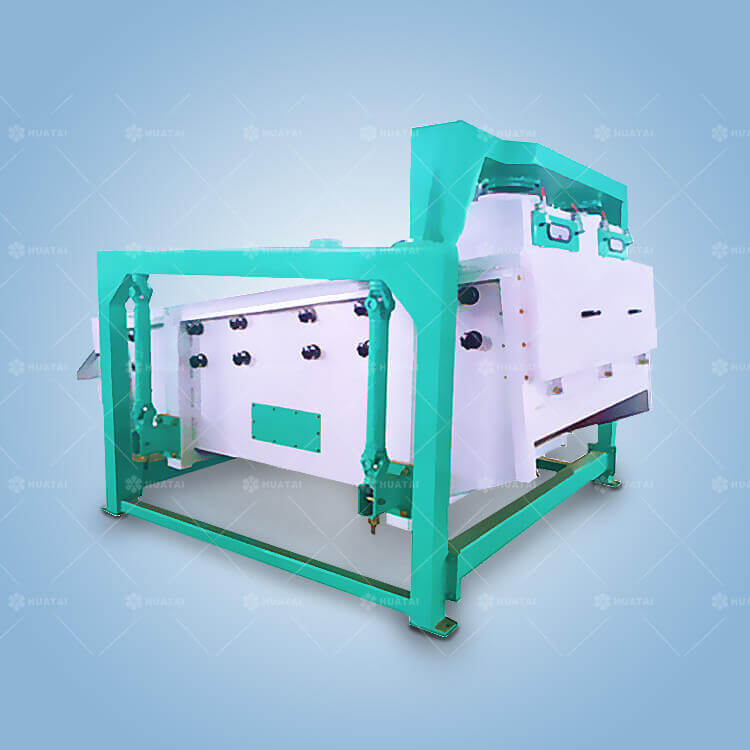

The TQLX-Efficient spin vibration sieve is mainly used for milling feed, rolling rice, cooking oil, and other industries of raw material cleaning and grading, and by changing the different pore size screen surface cleaning of granular materials.

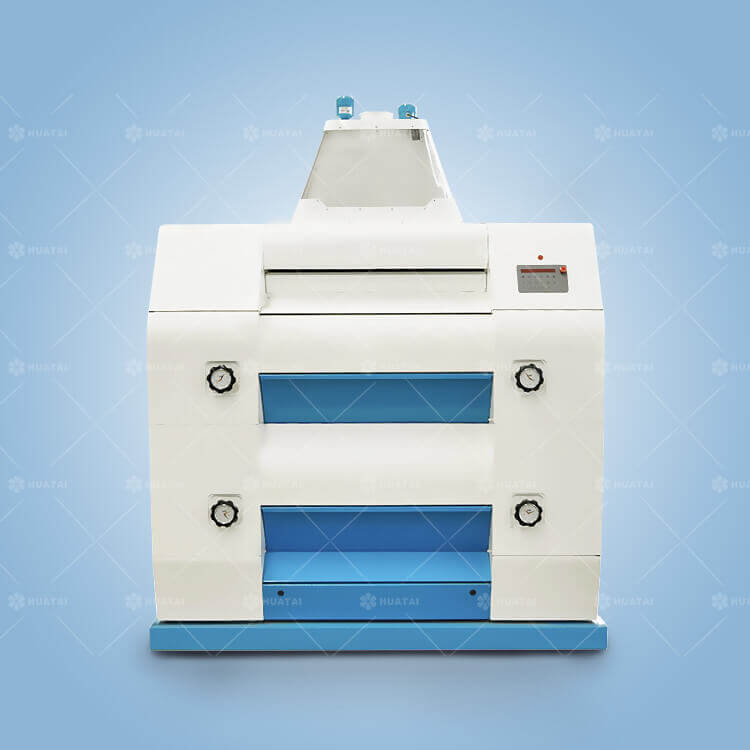

The MSQ-Pneumatic flour mills are mainly used for grinding grain and adopt pneumatic servo feed control system, a pair of rollers has different speeds, through this relative rotation peel wheat, and peel wheat endosperm skin off, then ground into flour.

Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.