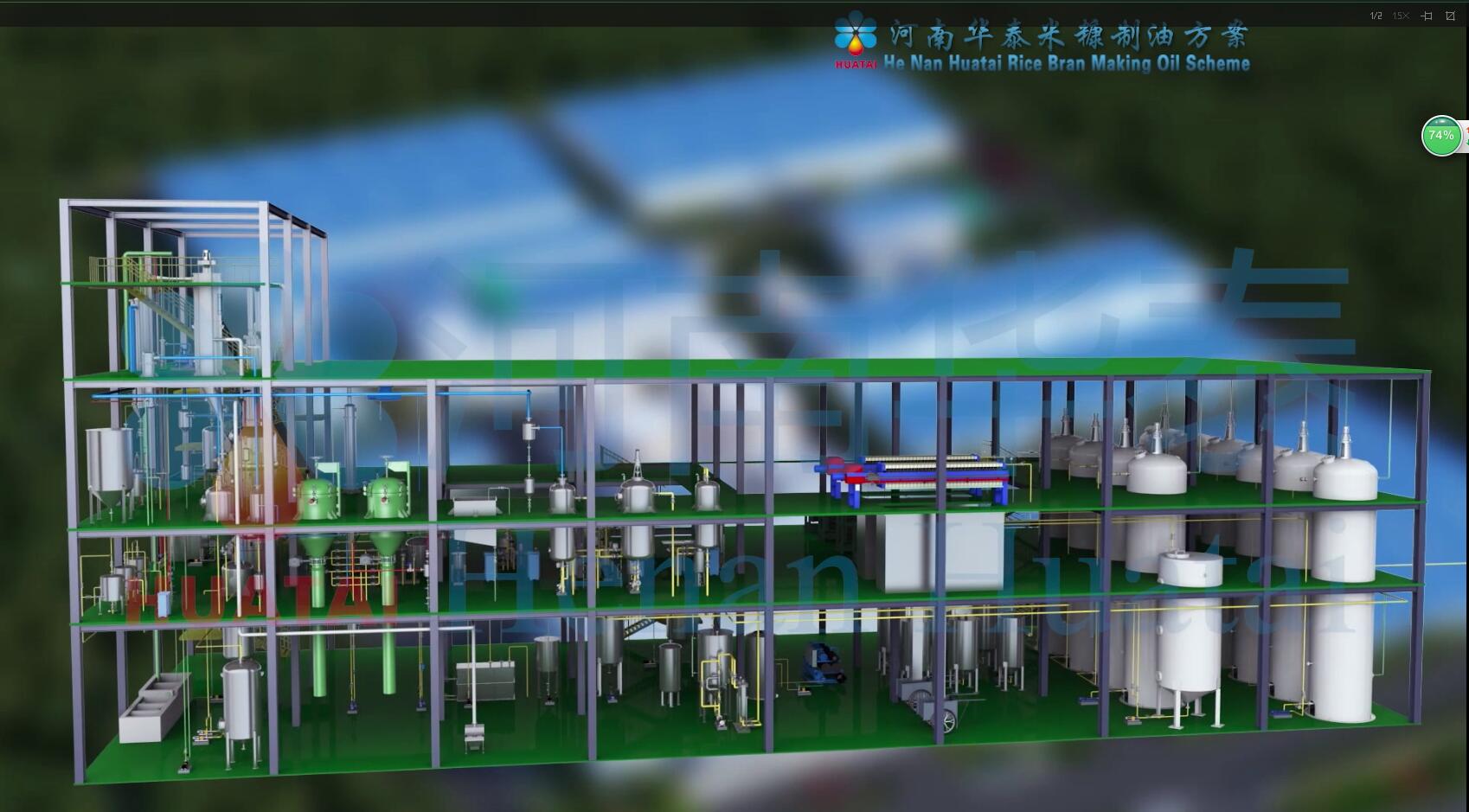

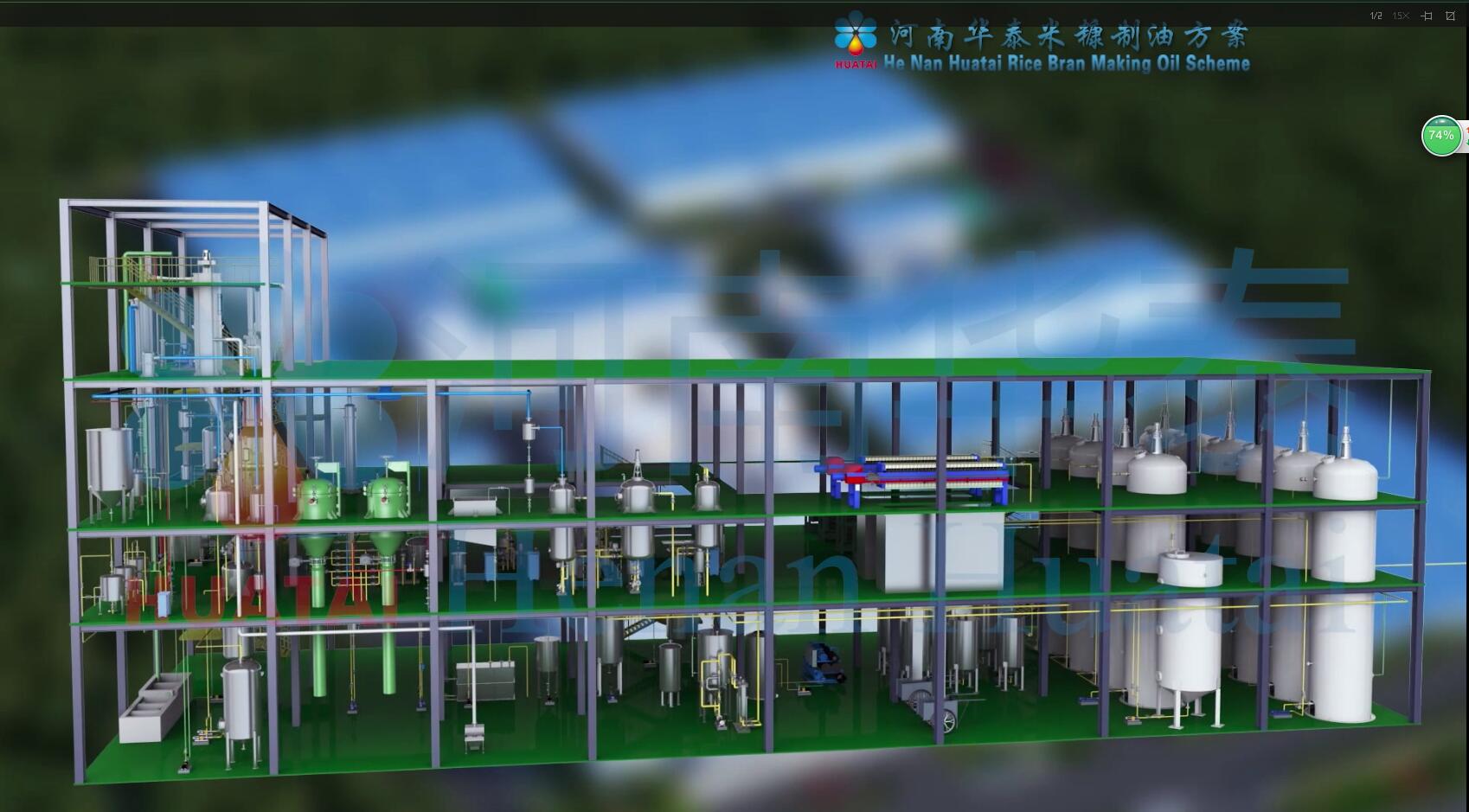

Refining is the process of removing the undesirable component from the substance. Vegetable oil refining plant is removing of unwanted substances from the vegetable oil and fat oil and make them valuable for use. It is carried out in three phases: first is neutralization, second is continuous bleaching process and third is deodorization process. Henan Huatai is one of the best refining machine equipment manufacture company which provides you the best refined and edible oil. They use the best technology in the refining process and work with dedication.

Alkali refining. Light up heat-conducting oil boiler, control heat conducting oil temperature of 98 degrees, and start the vacuum pump. Both low temperature and high temperature alkali refining are available basing on alkali concentration and oil temperature. High temperature alkali refining is only applicable for low acid value, light color, and low impurity crude oil refining.

● Washing. Heat the oil until 90 degrees after soapstock release, and add hot water for washing and stirring. Control water temperature 5-10 degrees higher than oil, or emulsification. Continuously stir mixture 5 minutes, keep stand 4 hours, emit soap water, and wash repeatedly 203 times. Stir and dehydration for 1 hours after clear oil temperature warmed to 105 degrees. Washed clear oil can be inhaled into decolorization boiler for vacuum dying 30 minutes.

● Decolorization. Vacuum pump with high vacuum of 700mmHg sends alkali oil to decolorization boiler. Keep stirring until temperature reaches 90 degrees, add decolorant (white clay, or active carbon) after moisture reduces less than 0.1%, and separate white clay from cooking oil by compressing air to oil filtration system to obtain decolorized cooking oil.

● Evaporation and deodorization. Evaporate and deodorize the cooking oil simultaneously while high vacuum reaches up 755mmHg. It takes 4 hours for deodorization under 240℃/ 755mmHg, 260℃/759mmHg with continuous steam distillation.