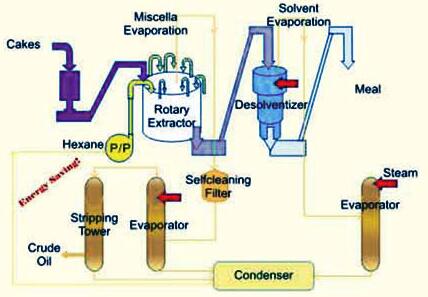

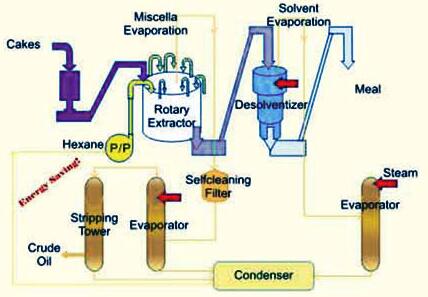

Main parts function of vegetable oil solvent extraction plant:

(1) Solvent pumps: continuously spray solvent to the rotary-typr extractor.

(2) Roary extractor: spray and soak the prepressed cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3) DTDC: used to separate the solvent from the wet meal.

(4) Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

(5) Miscella tank 2nd: the purified miscella will be pumped into it.

(6) Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7) Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Main Process of vegetable oil solvent extraction plant :

(1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is send to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Advantages of

vegetable oil solvent extraction plant:

(1) High oil yield, obvious economic benefit

(2) Less residual oil rate in the dry meal.

(3) Improving the quality of the meal.

(4) Low processing cost, high labor productivity.

Henan Huatai Cereals and Oils Machinery Co., Ltd., located in Hua County industry Zone of Henan Province, covering an area of 100,000sqm, with total investment RMB360 millions, has a modern standard plant and advanced processing equipment,we are a large scale cereals & oils machinery manufacturer integrating R&D, design, manufacture and installation. Over the years, Huatai Machinery has always been adhering to the development purposes of "to develop by excellent innovation, considering quality as the life”, and applies the brand management strategy of "high-lighting main products and cultivating specialty products", We have successfully obtained 29 national patents (including 9 invention patents), 6 international awards, 2 national awards and 2 provincial awards.