The processing of soybean oil mainly involves two methods: pressing and extraction. Each method has its characteristics, advantages, and disadvantages. The choice of method depends on various factors, such as the properties of the raw materials, production costs, product quality requirements, and consumer preferences.

Preserves Nutritional Components and Flavor: The pressing method extracts oil by applying mechanical pressure, effectively retaining the nutritional content and natural flavor of the oil, while avoiding solvent residue issues. Pressed oil is often rich in vitamin E and has a strong aroma.

No Solvent Residue: Since no chemical solvents are used, pressed oil does not contain residual solvents, making it safer and healthier for consumers.

Traditional Process: The pressing method has a long history. It combines modern technology with traditional techniques, and the produced oil is regarded as a pure, natural, and green food.

Lower Oil Yield: The oil yield from pressing is relatively low, leading to higher production costs and, consequently, a higher selling price.

Complex Process: The pressing process requires strict selection and pre-treatment of raw materials to ensure high-quality oil production.

High Oil Yield: The extraction method dissolves the oil in soybeans using chemical solvents, and then removes the solvents through heating and evaporation to obtain the oil. This method has a high oil yield of up to 99%, making it highly efficient.

Clear Oil Quality: Extracted oil has a clear color and fewer impurities, making it suitable for various food processing and cooking needs.

Lower Cost: Due to its high oil yield, the extraction method has lower production costs, making the oil more affordable.

Solvent Residue Issues: Since the extraction process uses chemical solvents, there may be concerns about residual solvents. Although refining processes can remove most solvent residues, strict production control is required to ensure oil safety.

Loss of Nutritional Components: During high-temperature refining, some nutritional components may be degraded or lost.

From the perspective of preserving nutritional content and natural flavor, the pressing method may have advantages. However, in terms of production efficiency, oil yield, and cost control, the extraction method is more favorable.

When choosing soybean oil, consumers can decide based on their needs and budget. As long as the oil meets national food quality and hygiene standards, both pressed and extracted oil are safe and reliable for consumption.

With technological advancements and increasing consumer demand for healthy diets, the oil industry continues to innovate and refine production processes to offer higher quality, safer, and healthier edible oils.

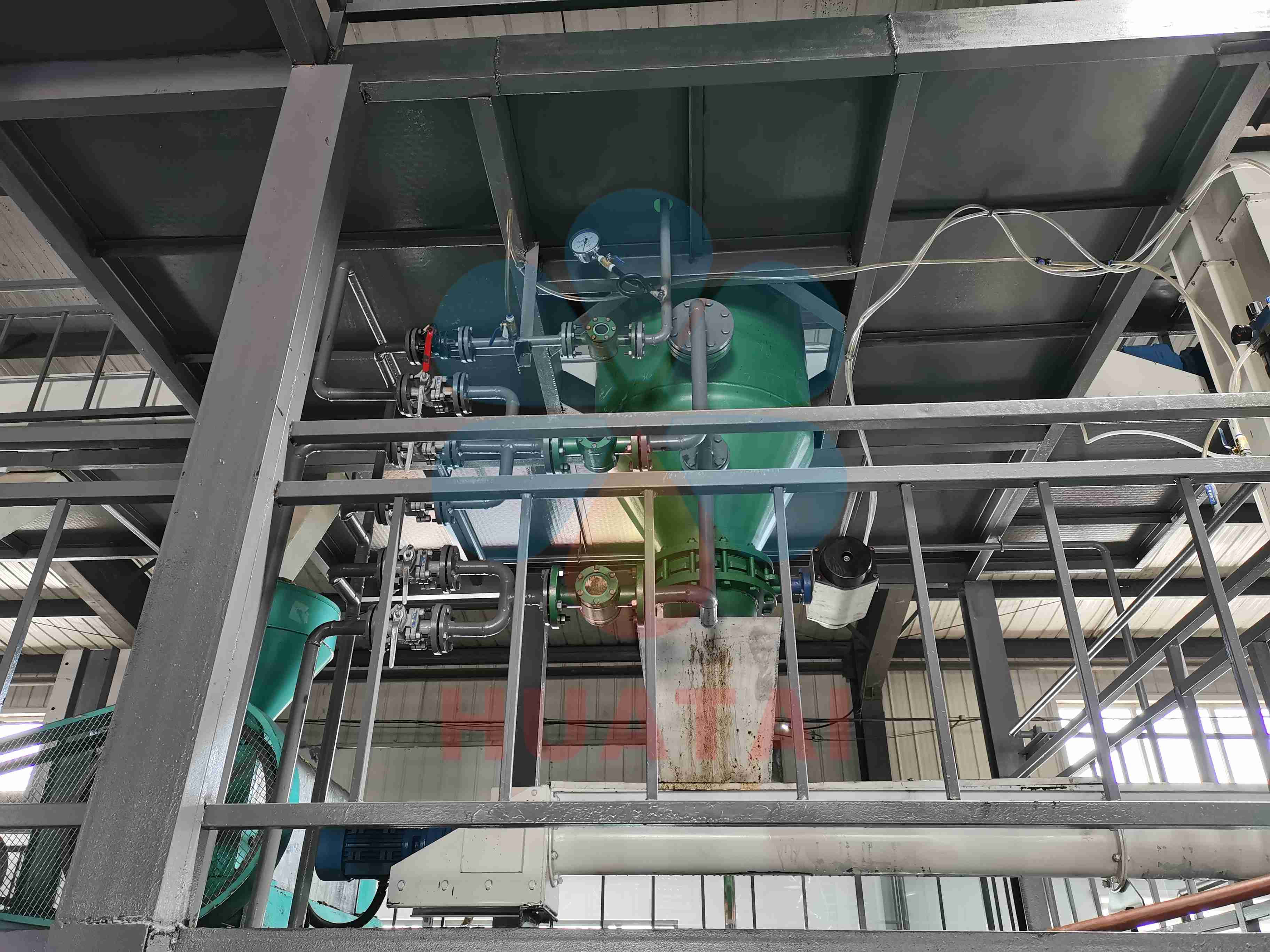

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.