Peony seed oil, renowned as "liquid gold" for its abundance of unsaturated fatty acids and alpha-linolenic acid, has garnered significant attention amid rising consumer demand for high-quality edible oils. Optimizing extraction yield and oil quality has become a central challenge for producers, making the selection of scientifically advanced production lines critical to achieving these objectives.

Although peony seed kernels possess an oil content of 30–40%, inefficient processing often diminishes actual yield. Conventional extraction methods are prone to high-temperature oxidation, which degrades heat-sensitive nutrients like alpha-linolenic acid, increases acid value, reduces smoke point, and compromises both stability and nutritional quality. Additional concerns such as impurity retention and turbidity further hinder product development. While mechanical pressing results in high residual oil, solvent extraction adversely affects flavor and nutritional integrity. Thus, producing high-grade peony seed oil requires carefully planned processing techniques and tailored production line design.

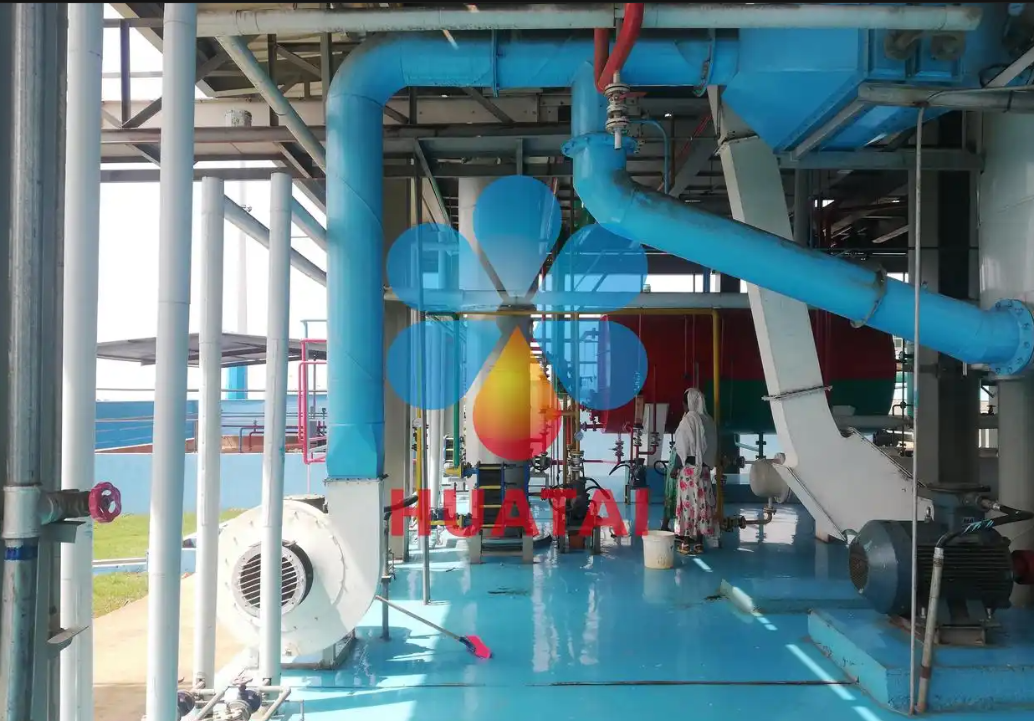

A standard oil extraction line comprises three key stages: pretreatment, pressing, and refining. Pretreatment establishes the foundation for oil yield; pressing influences both extraction efficiency and crude oil quality; and refining determines the final grade of the finished product.

Pretreatment enhances material purity and modifies structural properties to facilitate oil release. This stage includes cleaning, dehulling, and conditioning—processes that remove impurities such as stones and metallic debris to prevent equipment abrasion and oil contamination, eliminate hulls that impair yield and color, and soften cell walls through moisture and temperature control to improve oil mobility.

For the pressing stage, physical cold-pressing is recommended to better preserve nutritional and sensory qualities. Cold-press screw extruders are suitable for multi-stage pressing that reduces residual oil content. For superior quality, hydraulic presses offer static extraction that maximizes nutrient retention.

Refining should incorporate low-temperature hydration degumming and physical deacidification instead of traditional alkali refining to minimize nutrient loss. Activated clay adsorption and vacuum deodorization can effectively remove pigments and off-flavors while elevating the smoke point. Subsequent plate-and-frame filtration and centrifugal separation ensure minimal impurity levels in the final product.

Equipment configuration must be customized according to production scale, key technical requirements, and operational context. Each production line should be designed around capacity targets, core equipment specifications, and intended application scenarios.

An optimal production line prioritizes oil yield and quality at every stage. Oil producers must balance technical and economic considerations to establish sustainable, eco-friendly operations. Through scientifically-informed planning, manufacturers can enhance both efficiency and profitability while supporting long-term growth.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.