Overview

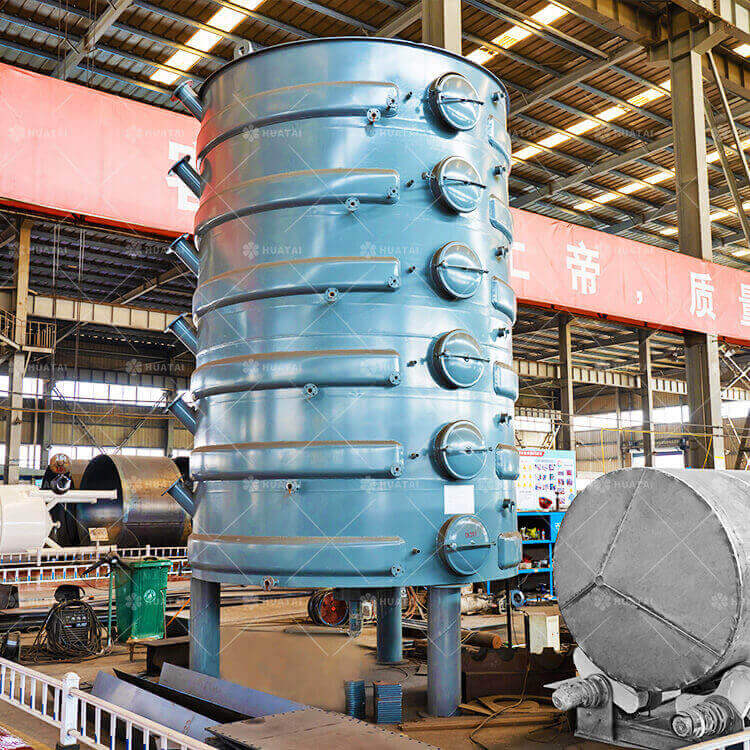

Oilseeds cooker is used for wetting and cooking the flakes from the flaking roll to meet the technological requirements of oil pressing or extracting, enhancing oil yield and improving the quality of crude oil. Oilseeds cooker is used in large scale oilseeds processing. It is suitable for cooking the flakes of peanut, soybean, rapeseed, sesame, cottonseed, camellia seed, sunflower seeds, copra, corn germ, etc. Oilseeds cooker can also be used as conditioner.

Features

GET A QUOTEOilseeds cooker is used for wetting and cooking the flakes from the flaking roll to meet the technological requirements of oil pressing or extracting, enhancing oil yield and improving the quality of crude oil. Oilseeds cooker is used in large scale oilseeds processing. It is suitable for cooking the flakes of peanut, soybean, rapeseed, sesame, cottonseed, camellia seed, sunflower seeds, copra, corn germ, etc. Oilseeds cooker can also be used as conditioner.

Oilseeds stack cooker adopts steam or conduction oil as heat source. The bottom and side of each layer have a steam jacket. The indirect team is introduced into the jacket to heat the flakes. Valves are adopted to adjust the steam so that to control the material temperature. The agitator blades at each layer mix the materials to ensure uniform cooking. The steam pipe under the agitator blades of the first layer rotates with the blades to spray the direct steam into the materials.

| Model | Capacity(t/d) | Power(kw) | Heating area (m2) | |

| softening | cooking | |||

| YZCL150×5 | 40-60 | 20-30 | 22 | 14.5 |

| YZCL180×5 | 80-100 | 40-50 | 30 | 20 |

| YZCL210×5 | 100-150 | 60-70 | 30 | 26.2 |

| YZCL250×5 | 160-200 | 80-90 | 37 | 42 |

| YZCL250×6 | 180-250 | 90-100 | 45 | 50.4 |

| YZCL280×5 | 220-260 | 110-130 | 55 | 52 |

| YZCL280×6 | 260-300 | 130-150 | 55 | 62 |

| YZCL300×5 | 250-300 | 120-140 | 55 | 56.8 |

| YZCL300×6 | 300-350 | 150-200 | 75 | 67 |

| YZCL400×5 | 550-600 | 280-300 | 110 | 89.4 |

| YZCL400×6 | 700-800 | 300-350 | 132 | 107 |

| YZCL400×7 | 800-900 | 350-400 | 132 | 120 |

Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.