Pumpkin seed oil, a healthy vegetable oil, is obtained by pressing pumpkin seeds. It is rich in polyunsaturated fatty acids, vitamin E, minerals, and antioxidants, offering significant health benefits such as lowering blood lipids, preventing thrombosis, reducing blood pressure, combating aging, and improving cardiovascular health. In recent years, with growing health awareness, pumpkin seed oil has gained increasing market favor as a natural health supplement.

Pumpkin seed oil is primarily categorized into two types based on processing methods: cold-pressed pumpkin seed oil and hot-pressed pumpkin seed oil.

This process is conducted at temperatures below 60°C. It maximizes the retention of the pumpkin seeds' natural flavor and nutritional components, especially polyunsaturated fatty acids (PUFAs) and vitamin E. However, due to its more delicate and precise nature, the production cost is relatively higher.

While this method may lead to some loss of nutrients, it offers high processing efficiency and strong economic viability, maintaining a certain market share.

In pumpkin seed oil processing, the pressing method is widely adopted for its superior nutrient retention, with the advantages of cold-pressing being particularly significant. The cold-pressing technique, through low-temperature extraction, significantly reduces nutrient loss in the oil, resulting in a product with greater health value. Consequently, cold-pressed products currently dominate the pumpkin seed oil market.

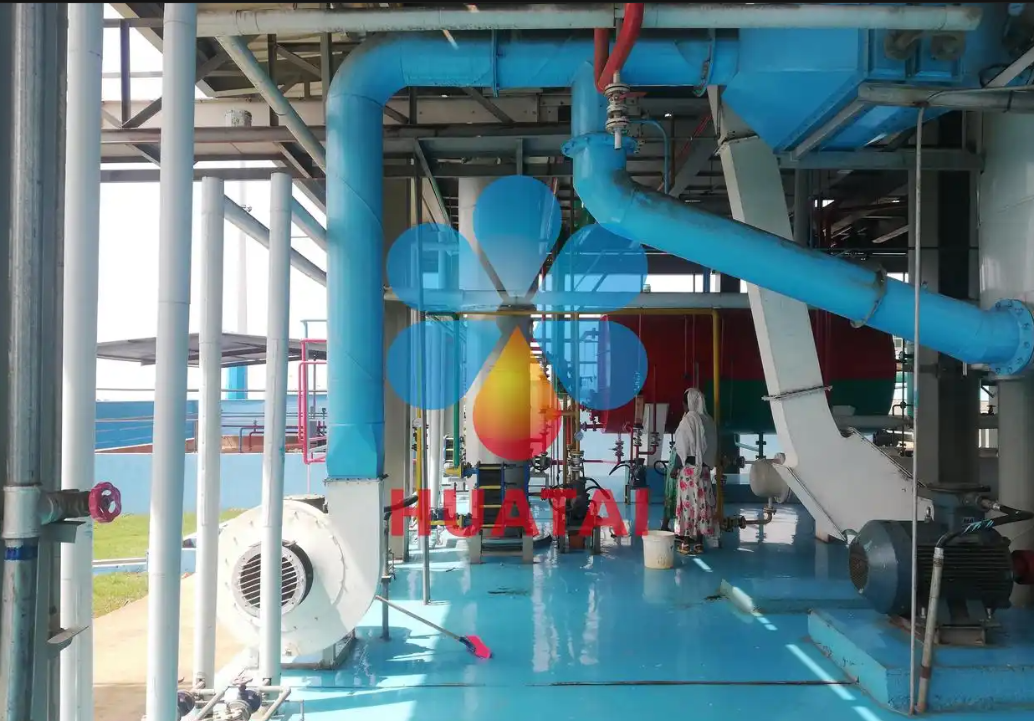

Pumpkin seed kernels are fed into a hydraulic oil press or cold-pressed using a screw oil press. The resulting crude pumpkin seed oil is then sent to refining equipment for processing to obtain the finished pumpkin seed oil. The main equipment for a cold-pressed pumpkin seed oil production line includes the oil press and oil refining equipment. Making the correct choices for these ensures smooth project operation.

Whether using a hydraulic press or screw press, manufacturers strive for excellence. These presses offer higher oil yield and preserve the nutritional quality of the oil, facilitating the production of compliant, high-standard pumpkin seed oil.

Refining pumpkin seed oil,this is a crucial step. Crude oil has limited edibility. Oil refining equipment effectively processes crude oil from various edible oil primary processing stages. It delivers excellent refining performance, producing oil that meets relevant standards and enabling smooth profit realization.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.